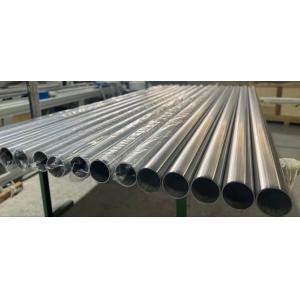

2024 6061 7075 Aluminum Tube 7075 T6 Seamless Thin Wall Aluminum Tubing

Aluminum Tube 7075 T6 Seamless Thin Wall Aluminum Tubing

has excellent stress corrosion resistance and high strength properties and is used in the manufacture of aircraft and high performance industries.

7075 alloys providing superior strength and elongation under stress.

The process starts with a hot billet being pierced by a mandrel. A ram is pushed against a die and forties out the aluminum. With a fores in excess of 4,000 tonnes the aluminum is extruded through the die and over the mandrel.

Aluminum Tube 7075 T6 Seamless Thin Wall Aluminum Tubing availability:

OD:12.7mm through 101.60mm

Walls: 0.5mm through 24.5mm

Tempers: T6

Typical Chemical Composition % | Weight % | Si | Fe | Cu | Mn | Mg | CR | Zn | TI | Each | Total |

| Minimum | | | 1.20 | | 2.10 | .18 | 5.10 | | | |

| Maximum | .40 | .50 | 2.00 | .30 | 2.90 | .28 | 6.10 | .20 | .05 | .15 |

Remainder Aluminum

Typical Mechanical Properties | Temper | Tensile | Hardness |

| | Ultimate | Yield | Elongation | Brinell |

| | KSI | MPA | KSI | MPA | % | |

| O | 33 | 228 | 15 | 103 | 17 | 60 |

| T6 | 83 | 572 | 73 | 503 | 11 | 150 |

| T73 | 73 | 503 | 63 | 434 | 13 | |